We are able to see on the BERG-blog which pages get the most hits, and funny thing one of the popular ones is the making of the huge wing joiner for the big DG500 , this was a blade type carbon joiner, but I use the aluminium tube/carbon joiners system on all other projects and these are easier to make.

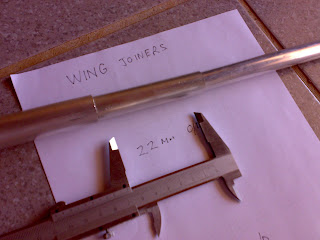

So as I needed to make new joiners for the Celstar I took lots of photos and will explain this simple way of making wing joiners for scale gliders up to 6mtrs.

I have been asked if a square joiner would be less likely to allow the wings to flutter, in theory that is true , in that the wing with a square tube cant rotate, but with a tube and a good locating pin setup I think the round joiner have the advantage in that the wing incedence can be altered totally and also between the left and right wings, with a square tube ,if built badly, it cant be adjusted as easily.

The aluminium tubes I use are available at most good hardware stores and are available in a variety of sizes with each outside diameter fitting within the next size I/D.

The small tube with a carbon tows filler works well on gliders to 4 mtr, the next size up tube

goes in the fuselage and in the wings. Size two with carbon will suit gliders up to 6mtrs, as the joiner and the largest size then goes into the wings.

If you choose a thick airfoil for foam wings, you can install the joiner tubes from the top of the root to the bottom skin and this will give the built in di-hedral , with a flat joiner.

The tubes are masked with tape.

The carbon is cut double length like a U , then I tie on some strong nylon line and check if dry they will pull through the tube, you can have a small gap to allow for the Epoxy .

The carbon is cut double length like a U , then I tie on some strong nylon line and check if dry they will pull through the tube, you can have a small gap to allow for the Epoxy .

I wet out a few carbon tows , at a time and use a slower curing epoxy to give plenty of working time. I picked up a problem with the bigger joiner as the wet out tows would not fit through, solution was to remove 4 x tows at a time until it just fitted. You need a handle of sorts, as every thing is slippery , I used a piece of cut tube to make a T handle wrapped with some tissue.

The big joiner has about 80 x 60k tows and the snaller one about 35 x 60K tows.

Epoxy was LR20 and harderner was SLC 60.

As always when working with epoxy ,wear gloves.

Once cured overnight, I trim the ends and clean off the masking tape ,you now have one very strong joiner, the big one weighs 447 grams but will be probably be the most important part of a 6mtr sailplane (the elevator being a close second).

B.T.W. the standard carbon joiner of 16mm diameter as used on my 6mtr Ventus did not break

during a verticle dive into the mountain side during last years Sungazer which destroyed the rest of the plane.

CHEERS.

No comments:

Post a Comment