The reason is that the next season starts early January and it would be great to fly these new creations and see how they do.They need to be completed fitted out and trimmed before the competitions start. Below there are some more photos of the secretive EMOYENE build similar in many ways to the STILLETO but here and there some clever techniques thrown in, check out these .

Accuracy plays a big part in getting a good result.

This team as you well know are really serious they have developed special tools to help them ,this one will be known as the home made pencil ----facinating.

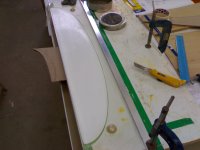

It is used as shown to mark the splitter board vertically below the fuselage plug , very neat idea.

This splitter is made up of several parts ,easy to remove off the mould later.

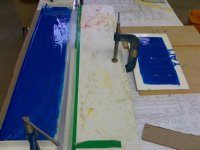

Meantime more preparation goes into the

plug. This is almost ready for paint.

plug. This is almost ready for paint.Keep at it , the clock is ticking.